Pull Production

When Toyota Production System (TPS) was first referred to as Lean Production in the 1980s by John Krafcik, the term gained wide proliferation, primarily through the bestseller books by James P. Womack and Daniel T. Jones: "The Machine that changed the World" and "Lean Thinking: Banish Waste and Create Wealth in Your Corporation".

Why precisely the term Lean was left standing, one can philosophize over, and one might think that for many this also resulted in unfortunate contexts.

In Womack & Jones' books Lean was used as a term and defined with Value, Value stream, Flow, Pull and Perfection. Still, it is often said that Lean is synonymous with Lean Production, and further related to the Toyota Production System (TPS) which is mainly portrayed as a set of process improvement techniques.

Unfortunately, this meant that we continued to call modern management Lean. When we say Lean Production, this should be seen as the effect of a philosophy, not the philosophy itself or the way of working.

Pull was emphasized as an important element in the definition of Lean Production, but the question is whether that should have been the headline?

Example

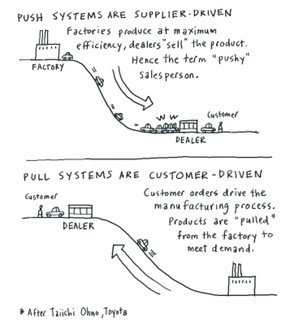

In the oil crisis of 1973, demand on the world market for cars was greatly reduced, and many automakers ended up with large stockpiles of semi-finished products and components throughout the value chain, but Toyota, with its pull philosophy, effectively stopped its own production and production at its subcontractors. As demand increased again after the crisis, most automakers faced challenges in getting full production started, Toyota, on the other hand, was quickly up to full pace based on its Pull philosophy and its management systems that immediately signaled the need for production throughout the value chain backwards in its own logistics and on to its subcontractors. See Roses, Christoph: All About Pull Production

In pull philosophy, it is the customer who defines the need, while the supplier has the power in a Push system.

Why Lean?

The word Lean makes us think of something that's lean. We envision starving people, and we are led to believe that a Lean organization is a starved organization. Opponents of Lean can use this belief. They say Lean goes beyond employees, that it's about reducing resources and saving costs. Some say that modern management is deadly: "that you use psychology to get people to make efforts over ability, that you should get employees to think about work around the clock and that people are manipulated into performing the maximum effort." It also often refers to Japanese culture and stories of overworked people.

However, modern leadership is not hunger lining or to saving money, there is something positive, something optimistic, something that looks up and forward, towards a vision. We will be the best, not by saving ourselves rich or pushing our efforts beyond reasonable limits, but by delivering according to expectations and continuously improving towards a common vision. Today's mindset can understandably lead many to wonder what Lean is, why we call it Lean and how Lean works.

Two hats, innovative and standard processes

We all have "two hats" in everyday life: 1. to perform daily tasks to, as much as possible, satisfy a customer and 2. improve the standard processes, so the organization develops in small steps towards a vision.

Continuous improvement is achieved with good and efficient standard processes and innovative processes carried out by an involved organization.

The standard processes are carried out by personnel with good training in carrying out the processes. The innovative processes are carried out by the people who work in the standard processes and know these well. Clear visions and target conditions and ongoing experimentation in the right direction mean that standard processes are becoming more efficient for the benefit of the customer.

Understanding The Pull effect

The pull effect is about putting the need or goal in focus and constantly being pulled forward by this. Normally this is linked to logistics and management of a material flow, but is also used in connection with, for example, marketing and hotel operations, and through what we call Kanban boards that introduce pull effect in, for example, development and improvement work. People in standard processes "on the floor" may well understand this. They know that it is the customer they are going to satisfy, provided that they have a culture and management that puts the customer in focus. However, if you arrive a little bit higher in the decision hierarchy, this becomes more unclear. There, one focuses on satisfying the interests of the owners, and ends up pushing solutions in one's own organization, and in the market to achieve short-term financial results.

The Pull system in improvement work

In the book Rother, Mike: Toyota Kata, Managing People for Improvement, Adaptiveness and Superior Results, we see how we train a pattern of improvement work and innovative processes. We have on a vision, we uncover challenges, we define target conditions, and we experiment with solutions. Here it is the vision that is the pulling force in the innovative process. This form of work introduces the Pull principle in improvement processes and problem solving in the same way as in standard processes. Toyota Kata, Managing People for Improvement, Adaptiveness and Superior Results, ser vi hvordan vi trener opp et mønster for forbedringsarbeid og innovative prosesser. Vi tar utgangspunkt i en visjon, vi avdekker utfordringer, vi definerer måltilstander og vi eksperimenterer med løsninger. Her er det visjonen som er trekkraften i den innovative prosessen. Denne arbeidsformen introduserer Pull prinsippet i forbedringsprosesser og problemløsning i like stor grad som i standard prosesser.

«Pull should be part of an overall continuous improvement kaizen strategy. Such an improvement should always start with the problem you want to solve”. Roser, Christoph. All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production (p. 377). AllAboutLean.com Publishing. Kindle Edition

Implementing reforms and investigating action plans is a Push system that is often used in the public sector. This should be abolished.

Pull as standard form of work

A Pull system can be adapted to all areas and processes, whether we are talking about standard processes and ongoing deliveries, or innovative processes, development processes or improvement processes. We will have a principle and system in which we do not push our own fads, solutions, or products on others, but listen to everyone's needs, follow our own vision, and contribute to all measures being pulled in the right direction. If we don't focus on a vision, a challenge and a target condition that pulls us forward, then we just push random ideas in arbitrary directions, and get no real progress. Then I do not only think of pull philosophy as system thinking in logistics, but as an overall philosophy in all process thinking.

Whether a measure is right or wrong according to a plan is subordinate. This is going to be some kind of battle over who's right. Is it mine or your measure that's right? It's almost like listening to an argument in a kindergarten. "My dad is stronger than your dad," or "I'm the one who said it first," "no, that was me."

We see new presidents and governments listing measures they are going to carry out in the first 100 days of their reign, and we are seeing election leaflets and hear in debates about measures that are important. In times of crisis, politicians come up with one idea after another, but it is the very way of working that is important, not the list of measures. The measures listed in a plan are never correct anyway. It should either be a standard action to satisfy the needs of a customer, carried out by experienced people in good standard processes, or an experiment carried out to verify a hypothesis in the direction of a common vision towards ever better deliveries to customers.

Pull is not just a production method

Pull is mainly in all literature related to Lean Production and TPS, and this form of work is very central to production and logistics. But Pull is a principle that should govern all processes, whether in management, support processes, information or otherwise.

Pull is all about

- What you want

- When you want it

- In the amount you want it

No matter what process you have or which delivery you are responsible for, your ideal approach is a Pull principle. The recipient shall receive what he wants, when he needs it and in the amount he wants.

The Pull philosophy should have been the basis for the way of working throughout society and in all organizations. Not only in standard processes, but in at least equal degree in innovative processes. The customer's needs should control the deliverables, it is not the supplier who should decide what is best for the customer. Experiments must be pulled towards the target condition, challenge, and vision, it is not the management that should manage activities through an action plan. Unfortunately, it is the Push philosophy that is preferred by leaders, politicians, teachers, financial elite, and the media both in standard processes, improvement processes and development processes. We need to get away from controlling activity management and action plans.

If we had called it Pull instead of Lean, we might have broader acceptance of this as a way of working.